Stainless Steel Filter Screen - Type AISI 904L and 316L

Filter elements of the following material:

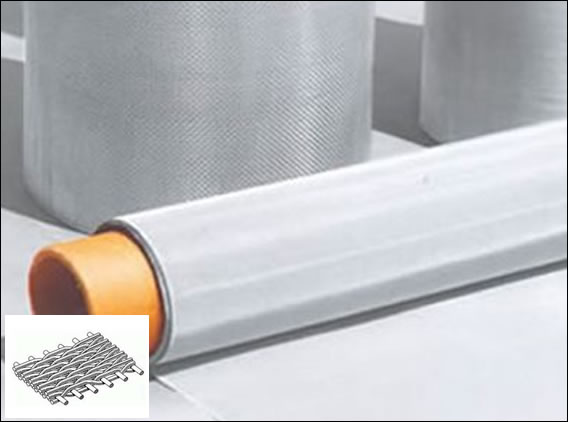

Model SSWM-2411-0304: Filter screen 24x110 mesh, wire 0,36/0,26mm, Material: 1.4539 AISI 904L, Rolls: 15m x 100 m

Model SSWM-2411-0216: Filterscreen 24x110 mesh, wire 0,26/0,36mm, Material: 1.4404 AISI 316L, Rolls: 15m x 100 m

Model SSWM-1330-0216: Filterscreen 130 x 30 mesh, wire 0,20/0,40mm, Material: 1.4404 AISI 316L, Rolls: 15m x 100 m

Model SSWM-1330-0204: Filterscreen 130 x 30 mesh, wire 0,20/0,40mm, Material: 1.4539 AISI 904L, Rolls: 15m x 100 m

Model SSWM-1330-1516: Stainless steel strips: AISI 316L, thickness 1,50mm, width 88mm finish 2B Cold rolled

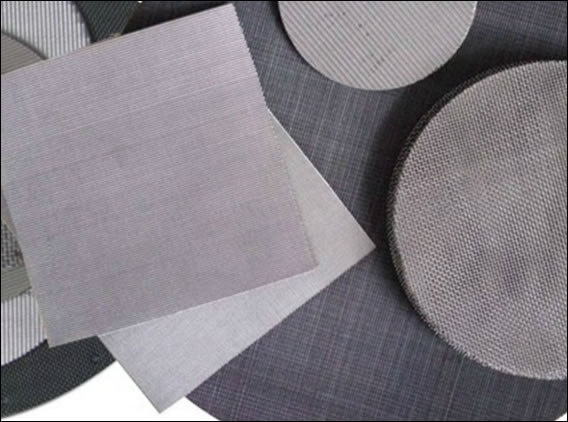

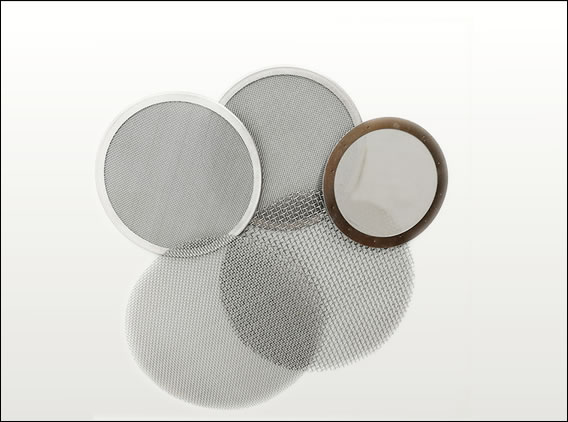

We manufacture filter grade stainless steel hardware cloth and fabricate the wire cloth into discs, slit into circles, or cut into strips / pieces.

BASIC INFORMATION

Materials: AISI 430, 302, 321, 304, 304L, 316, 316L, 904L, Monel, Inconel and other Alloy metals.

904L Stainless Steel Material

904L steel is commonly used in the high-tech, aerospace and chemical industries. Its outstanding corrosion resistance is comparable to that of precious metals. 904L and 316L have the samilar main components are nickel, chromium, molybdenum, but the ratio is different. The biggest difference between 904L and 316L is the content of chrome metal in the material. 904L steel contains more chromium. Chromium can help the surface of metal materials to form anti-corrosion protective film, so the corrosion resistance is stronger than 316L.

AISI304:

Type 304 often refers to as "18-8" (18% chromium, 8% nickel ). T-304 is the basic stainless alloy mostly commonly utilized for wire cloth weaving. It withstands outdoor exposure without rusting and resists oxidation at an elevated temperature up to 1400 Degrees Fahrenheit. Type 304 L is very similar to T-304, the difference being the reduced carbon content for better weaving and secondary welding characteristics.

AISI316:

Type 316: Stabilized by the addition of 2% molybdenum, T-316 is an "18-8" alloy. Type 316 has better resistance to pitting corrosion than the other chromium-nickel stainless steels where brines, sulfur-bearing water or halogen salts, such as chlorides are present. Type 316 L: Type 316 L is very similar to T-316, the difference being the reduced carbon content for better wire cloth weaving and secondary welding characteristics. 316L steel is mainly used in food processing and medical instrument.

AISI 316 L:

Very similar to AISI316, yet with the reduced carbon content for better wire cloth weaving. Woven wire of 316L offers excellent resistance against acid, alkali, heat and corrosion, extensively used in processing of oil, chemical, food, making wire mesh filter, also sorting and screening of solid, liquid and gas in mine, metallurgy, airspace and machine making.

Monel Steel:

The monel steel is also known as Nickel-copper alloy material as its main chemical components are nickel and copper. Monel series material series include Monel400,Monel401, Monel404, MonelR405 and Monel K-500. The most popular monel mesh is made of Monel 400 or Monel K-500.

Monel wire mesh has 60% up of nickel content which offers intense resistance to the variety of corrosion conditions such as resistance to brackish water, steam, salt and caustic solutions. Also, the melting point of Monel material is 1300 to 1350 and this enables Monel wire mesh products suitable for high temperature working conditions. Monel steel mesh is often used in research and development of petroleum and ocean exploring activities.

Weaving: Plain, Twill, Dutch Weave, Five Heddle Weave

Plain Weave Wire Mesh

Among all woven wire products, Plain woven stainless steel wire mesh has the maximum opening and the minimum thickness of the fabric.

Features: Square aperture, high flow through, relative high open area as result of less pressure drop during filtration.

Uses: Plain woven wire cloth is suitable for all kinds of filtration up to 63 µm.

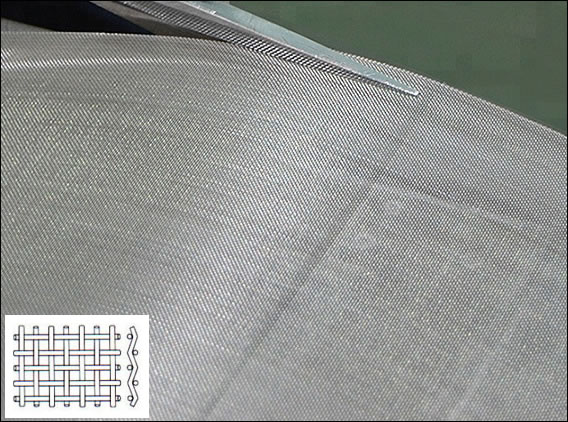

Twill Weave Wire Mesh

Twill weave is applied for weaving of heavy meshes and thicker wire fabric with square opening compared with Plain Weave. Each weft wire passes over two and under two warp wires, and each warp wire passes over and under two weft wires. The wire diameter for both (warp and weft) is mostly the same. Twill Weave allows a thicker wire and is suitable for heavy meshes. The wire position of Twill weave wire mesh is less stable compared with plain weave.

Features: Twill woven wire mesh has square aperture, it is less rigid than plain weave, easy deforming. It is a strong wire cloth due to ratio of wire diameter and aperture.

Uses: Twill woven wire mesh is mostly used for filtration between 25 to 130 μm, processed into discs, packs, filter baskets or various filter elements.

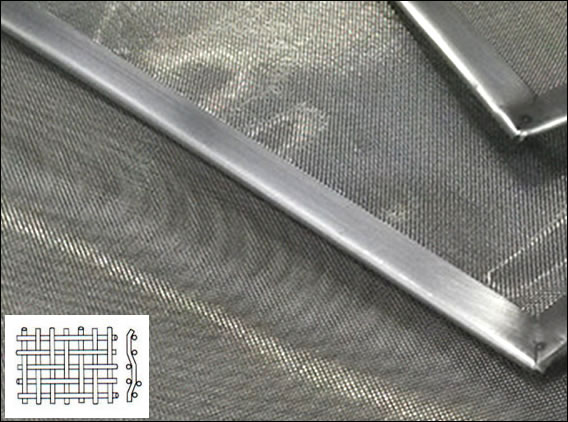

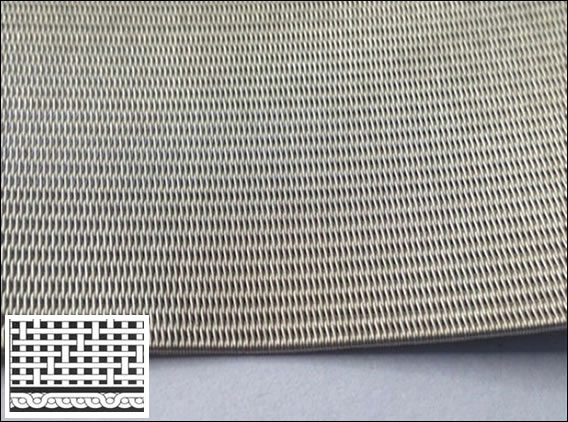

Dutch ( Plain) Weave Wire Mesh

Dutch plain woven wire mesh has straight warp wires and close weft wires. The weft wires lie as close as possible against each other in a linen weave forming a dense strong material with small, irregular and twisting passageways that appear triangular when diagonally viewing the weave .

Compared with normal Plain Weave, the warp wires of the Dutch Plain are larger in diameter than the weft wires. This allows a greater mesh count in the weft direction for the Dutch Plain Woven wire products. Plain Dutch Weave is similar to plain weave, while the warp wires are thicker and lie closer to each other.

Features: Dutch plain woven wire is more solid than square or rectangular mesh, offering relatively high open area, suitable for all kinds of pressure filtration.

Uses:

1, Industrial filter cloth and apparatus of separation;

2, Gas and liquid filtration and other medium separation;

3, Precision pressure filters, the fuel filter, vacuum filter, as filter materials, aerospace, oil refining, pharmaceutical, sugaring, oil, chemical, chemical fiber, rubber, tire manufacturing, metallurgy, food, health research,etc.

Dutch (Twill) Weave Wire Mesh

Dutch Twill also known as Crossed twilled wire mesh. This type of woven wire mesh is a kind of twilled woven wire product combined with the Hollander Weave or Dutch weave. This pattern enables a strong wire cloth with super fine filtration. Compared with common Twill Weave, the Dutch twill allows a thick structure and a fine filter material.

Features: Dutch twill woven ss mesh is rigid, stable and robust.

Uses: For the production of filter disk screen and filter cartridges, used in chemical industry, medicine, petroleum, telecom-communication, scientific research units and so on.

Dutch Weave (Reverse Dutch Weave) Wire Mesh

Reverse Dutch weave is applied for optimizing filtering media manufacture thanks to a high percentage crossing/opening surface. By varying the combination of weft and warp wires, filtering ratings from 14 to 100 microns can be obtained, with an available crossing or opening surface of 30-40%, the maximum yield in similar conditions.

Compared with Plain and Twill weave wire mesh, Dutch Reverse Wire Mesh (actually all the Dutch woven wire mesh) has an improved mesh thickness, filteration precision and service life. The warp wire, weft wire and density have great contrast which enables an excellent filteration under strains and pressure.

Features:

Acid proof, alkali proof, high temperature resistance, high resistance to wear, fine iltering performance, high precision,etc.

Uses: Reverse Dutch Woven Wire Mesh is applicable in a variety of extruders such as PP, HDPE, LDPE, PS as filter screen

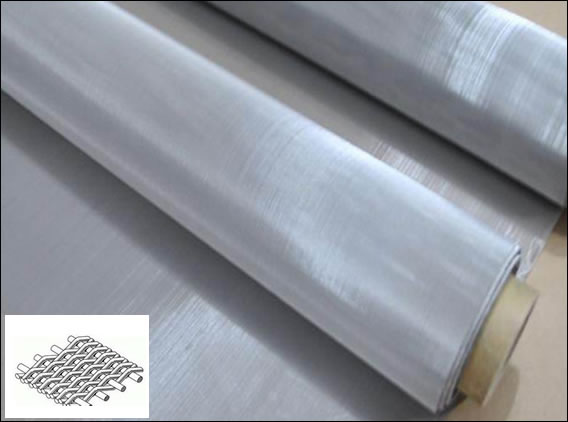

Five-Heddle Woven Wire Mesh

Multi-heddle weaving pattern, features a smooth top surface and an open lower surface of the woven wire mesh. This type of woven filter mesh is ideal to conduct accurate filteration under high mechanical strength. Popular meshes are 108x59mesh, 110x60mesh and 38x38mesh.

Uses: Mostly as filter belts / ribbons / cut strips for industries include aviation, aerospace, printing, dyeing, electronics, mining, pharmaceutical, food, processing and chemical industry.

Custom Service Available

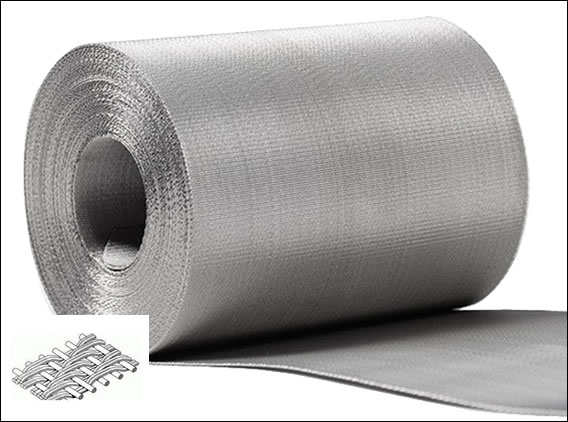

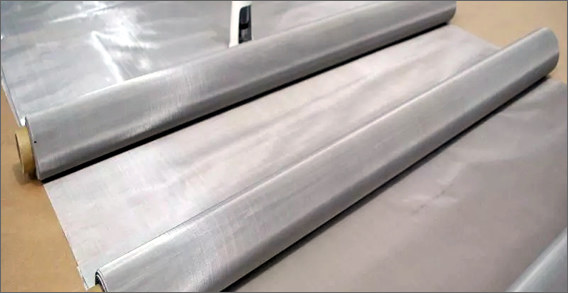

Available in rolls, panels, cut pieces or strips.

Can be supplied in custom wire gauges and meshes upon request.

Samples of cut strips or pieces provided for most ss meshes, full sizes samples can be provided for mesh discs.

The filter cloth discs can be made with or without rims, multi layer, rims can be different metals.

PRODUCTS MANUFACTURED AND SUPPLIED

( With models and details)

Stainless Steel Wire Mesh

Supplied for gas and oil industry

Reference lists in PDF

Stainless Steel Wire Cloth, Model SSWM-32-06

Stainless Steel Wire Cloth

MESH-32 per inch

Wire Dia 0.0065"

Width of opening 0.0248"

Open area 62.7%

Stainless Steel Woven Wire Cloth, Material 304, to Egypt

Model SSWM-8807: Stainless Steel Wire Cloth, 8 x 8 mesh, 0.7mm wire diameter, 1m width rolls

Model SSWM-8010: Stainless Steel Wire Cloth, 80 x 80 mesh, 1mm wire diameter, 1.22m width rolls

Model SSWM-4410: Stainless Steel Wire Cloth, 304 Grade, 4 x 4 mesh, 1mm wire diameter, 1.5m width rolls

Stainless Mesh, Model SSWM-30-25

Material: Stainless Steel 304 or 316

Mesh: 30 X 250 Mesh

Wire: .010 X .008 wire diameter

Rolls: 4' X 100' rolls.

Metal SS Wire Cloth, Plain Square Weave

Model SSWM-17-25:

Materials: 17-4 PH Stainless Steel and 17-7 PH Stainless Steel

Weaving: Plain square weave

Wire Diameter: .060 to 0.1 "

Openings: 0.25 to 0.5 "

FREE PDF FOR customers

FREE PDF FOR customers Site map

Site map Support +0086 186 189 2345

Support +0086 186 189 2345 HuaHAI E-mail

HuaHAI E-mail