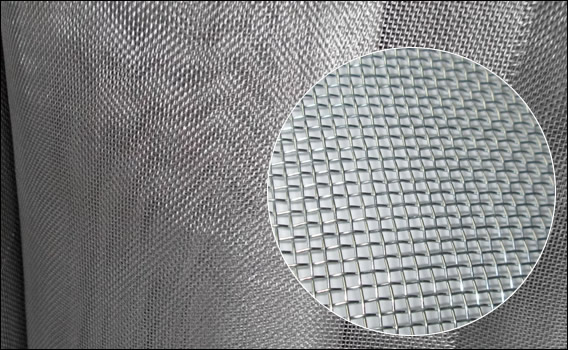

Also known as Galvanized Mesh.

BASIC INFORMATION

Manufacturing: Weaving or Welding

Galvanized mesh hardware cloths can be classified into Woven Wire Galvanized Hardware Cloth ( square hole ) and Welded Wire Galvanized Hardware Cloth ( square hole and rectagular hole ) . Hardware cloths manufactured through Welding or Weaving processing, will result in different structure, property and final applications.

Galvanizing: Galvanized Before or After Weaving / Welding Processing

The galvanizing of the meshes can be done before or after the weaving or welding. The latter processing enables thorough zinc plating to the hardware cloth and makes it stronger. A further vinyl or powder coating can be made to the hardware cloth at customers demand.

Galvanized hardware cloth woven mesh or welded mesh can also divided into electro galvanized or HDG (hot-dipped galvanized) according to the galvanizing treatment. Electro galvanized mesh hardware cloth is less cost compared with HDG one as the later used more zinc material in plating and it takes more time to work on it. HDG galvanizing has a thicker zinc coating and it offers good corrosion resistance, bright appearance, long service life and other features.

Popular Manufacturing Types Applied for Galvanized Meshes:

pre galvanized before welded;

hot dipped galvanizd after welded;

galvanized woven mesh, electro or hot dip galvanized.

Pre-galvanized wire mesh is the most economical but is more prone to corrosion because the galvanized surface is burned off where the wires are welded.

Hardware wire cloth can be supplied in rolls, or cut into strips / pieces.

PRODUCTS MANUFACTURED AND SUPPLIED (Varieties with Hole Sizes)

Square hole Galv. hardware cloth is made of galvanized iron wire by plain or twill weaving. Galvanized woven wire mesh has precision construction, uniform mesh, fine rust-resisting and durable function.

Packing: In rolls,wrapped with waterproof paper then covered with hessian-cloth. Special packing may be arranged if necessary.

Application:

Woven galvanized wire cloth is widely used in making grain sieve, industrial sieves in sugar, chemical, stone crusher industries, filter liquid and gas, mosquito and window netting.

Woven wire galvanized mesh with different holes and treatments are used in different work environments:

Common Gauges and Meshes:

| Wire Gauge (BWG) mesh/inch |

Wire Gauge (BWG) mesh/inch |

| 3meshX21BWGX3'X100' | 22meshX33BWGX3'X100' |

| 4meshX23BWG | 24meshX35BWG |

| 5meshX24BWG | 25meshX35BWG |

| 6meshX25BWG | 26meshX36BWGX1mX25m |

| 8meshX24BWG | 26meshX36BWGX3'X100' |

| 8meshX26BWG | 28meshX36BWG |

| 10meshX27BWG | 30meshX36BWG |

| 10meshX28BWG | 30meshX36BWGX1mX25m |

| 12meshX29BWG | 30meshX36.5BWGX1mX25m |

| 14meshX28BWG | 35meshX36BWGX3'X100' |

| 14meshX30BWG | 40meshX38BWG |

| 16meshX30BWG | 40meshX38BWGX1mX25m |

| 18meshX30BWG | 45meshX38BWGX3'X100' |

| 20meshX32BWG | 50meshX38BWG |

| 20meshX33BWG | 60meshX38BWG |

| 22meshX32BWG | - |

FREE PDF FOR customers

FREE PDF FOR customers Site map

Site map Support +0086 186 189 2345

Support +0086 186 189 2345 HuaHAI E-mail

HuaHAI E-mail